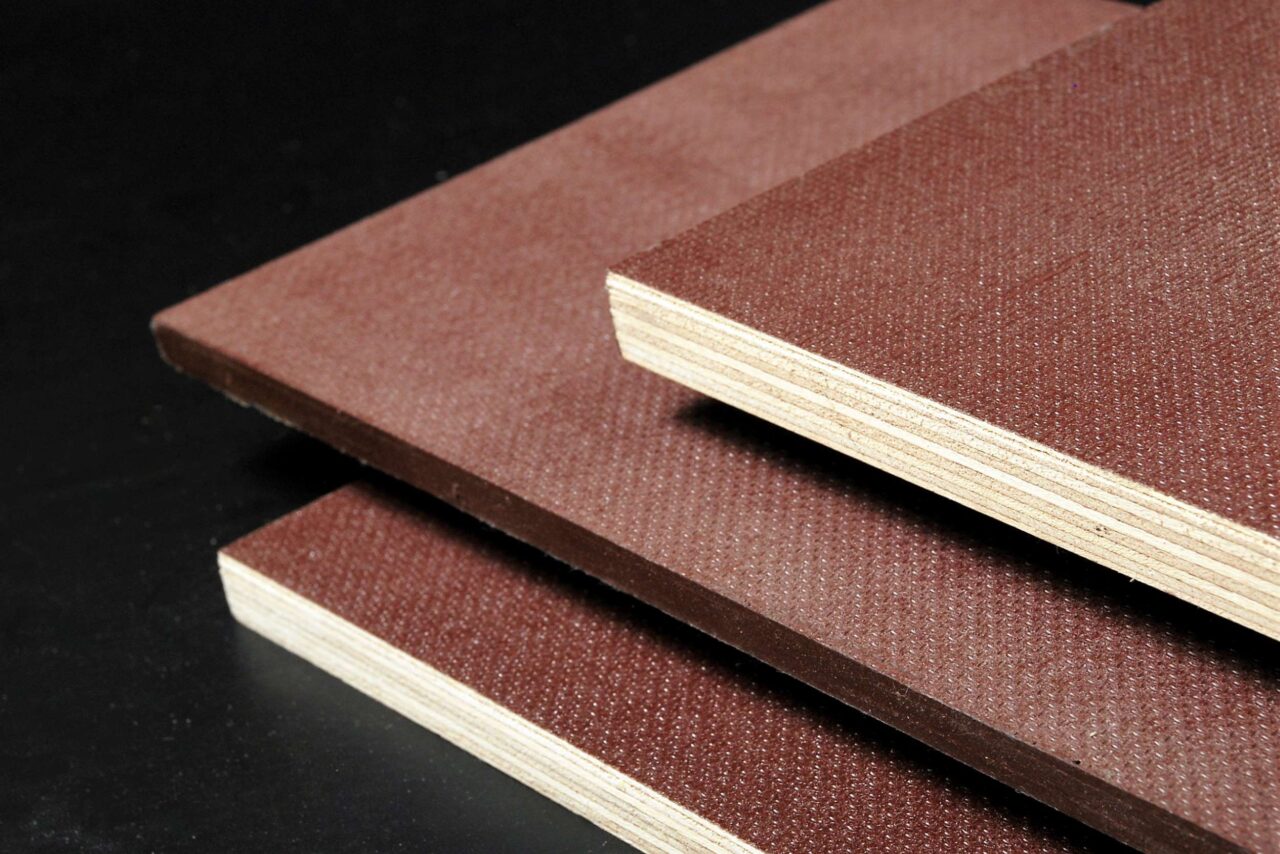

Plywood

The plywood panels are glued crosswise with a water-resistant phenolic resin. The gluing meets the requirements of EN 314-2 class 3 – the highest gluing class for plywood for outdoor use.

Taber abraser test: 450 – 500 rotations

Surface

- Anti slip surface:

Phenolic resin film brown 240 g/m² with wiremesh structure.

- Backside:

Phenolic resin film brown 120 g/m² with smooth surface

Other coatings or colors on request.

Edges sealed with an acrylic varnish brown.

Application

Welde Robusta SIEB/FILM plywood panels are particularly suitable for bottoms in the automotive sector like:

Vans, small trailers, truck setups

Nevertheless also in the area of warehouse, laodingplattform, flight cases or scaffolding.

Plywood thickness

| Thickness in mm | Number of veneers | Weight in kg/m2 | Weight/pack in kg | Number of sheets/pack |

|---|---|---|---|---|

| 15 | 7 | 7,00 | 1520 | 67 |

| 18 | 9 | 8,30 | 1520 | 56 |

| 21 | 9 | 9,90 | 1520 | 48 |

Other thickness on request

Plywood dimensions

1250 x 2500 mm/ 2500 x 1250 mm (only on request)

Tolerance length/width: according to EN 315

Wood moisture 10% +/- 2%

Structural properties

| Thickness in mm (EN 315) |

E-Modul in N/mm2 (EN 310) |

Bending strength in N/mm2 (EN 310) |

||

|---|---|---|---|---|

| Em5%II | Em5%┴ | fm5%II | fm5%┴ | |

| 15 | 3330 | 2766 | 32 | 28,5 |

| 18 | 3330 | 1946 | 31 | 29,7 |

| 21 | 4197 | 1943 | 31,3 | 23,3 |

Other panel thicknesses on request

FSC® or PEFC® compliant delivery is possible on request